Specifications

Standard or Nonstandard:Standard

Type:Roller Chain, water Sewage treatment

Material:Alloy

Tensile Strength:Strong

Place of Origin:Zhejiang, China (Mainland)

Brand Name:Gervi

Model Number:ANSI122303

Color:Nature

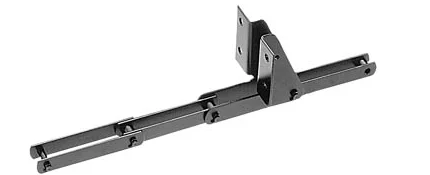

Name:Sewage Treatment chains Coal Mining Conveyor Chain

Structure:Heat treatment Plate Chain

Payment:T/T

Function:Transmisssion water Sewage treatment

Certificate:ISO9001:2000

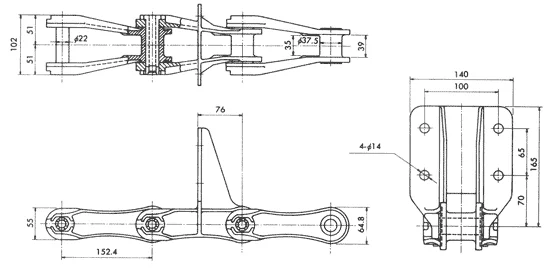

Pitch:4.7625mm-76.2mm

Treatment:Heat-treatment

product name:Sewage treatment transmission chain for work plants Drive Bushchains

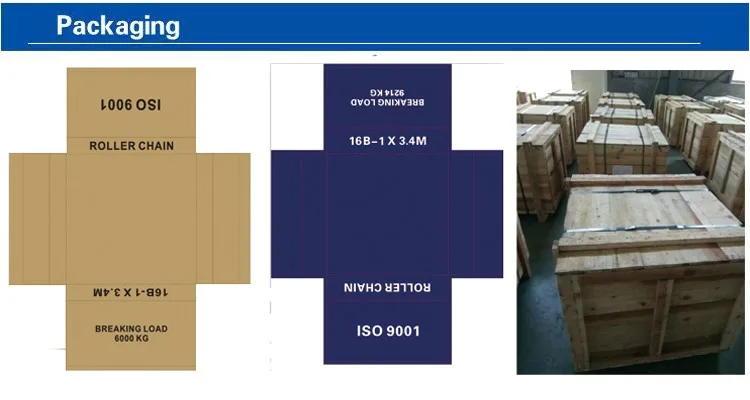

Packaging & Delivery

Packaging Details:

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

Carton Box+Wood Case+Container Or according to customer's requirements

Delivery Detail:15 days after payment

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

Application for Roller chain

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

Selection and Handling

The chain speed of a scraper application is slow, 0.3 to 0.6 m/min., and 3 m/min. in the bucket application. The chain tension is the highest during the test period, before water is poured into the tank. Before water is poured into a 40-m tank, one chain is exposed to tension of 10 kN.403 stainless steel chain has sufficient corrosion resistance for most sewage facilities. If there is a high concentration of chlorine (as found in sea water, for example), if there are high levels of sulfur from hot springs, or if the tanks are contaminated, 304 stainless steel should be used, at least for side plates.

Chains for Special Applications

Chains used in water treatment applications are operated at low speeds and not subjected to any heavy shock loads. It is not necessary in this application to consider chains with tensile strength greater than 19 tonf.

For that reason the following chains were developed:

ACR 810 Chain is a small chain made of 403 stainless steel. It has a tensile strength of 10 tonf. This was the first chain to be used in scraper applications to be equipped with rollers. The rollers reduce wear on the sprocket and the chain. Insert-tooth sprockets have been developed for this chain as well. (See Figure 6.30.)Engineered plastic chain (ACP Chain, Figure 6.31), developed in the United States, is a light-weight chain with high corrosion resistance. It does not have rollers (similar to cast iron chain). Due to its light weight (one-half to one-fourth the weight of stainless steel chain), installation is relatively simple.

One of the problems with this chain is that engineered plastic expands and contracts as the water temperature changes. Therefore, it is difficult to keep the chain under constant tension. Tensile strength (25 to 40 kN) is much lower than either cast iron or stainless steel chain.

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

We have machinery processing from raw materials to finished products and a full set of quality testing equipment. Mechanical processing equipment include punching machines, milling machines, planing machines, grinding machines, sawing machines, gas welding machines furnaces, box-type furnaces, pit furnaces, continuous mesh belt furnaces, and clearance sand shot blasting machines. Testing equipment include high-speed carbon sulfur analyzers, elemental analyzers, hardness testers, metallographic analyzers, chain length measuring instruments, WEW-100B Rally test machines, 0-9000 length measuring platforms. Our company has passed ISO9002 quality system certification

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

Company Information

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

Gervi is a leading manufacturer of a wide range of industrial use power transmission components and equipment.

Differentiating quality, technology development and production systems rather than just simply pursuing cost reductions we believe is a primary goal for Gervi. By forward thinking investment, a fine example being the construction of probably the world’s largest state of the art roller chain manufacturing plant ever by Gervi.

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

FAQ

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

1. Are you manufacturer or trade Company?

We are a factory founded in 1991 with trade team for international service.

2. What terms of payment you usually use?

T/T 30% deposit and 70% against document, Western Union, L/C at sight

3. what is your lead time for your goods?

Normally 45 days after confirmed order. 30 days could be available in low season for some items (during May to July), and 65 days during new year and hot season ( Jan to March).

4. Do you attend any Show?

We attend Hannover show in Germany, NMW in Austrilia, Canton fair, PTC, in China and many other specialshows.

5. What is the quality guarantee?

We guarantee 2 year quality.If any defect within 2 years,we send free goods with free shipping.

6. Can I have same samples?

Q: Yes. Please send us your contact details and then we can send you our samples.

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

More knowledges for Gervi:

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

From its advanced production facility in Letchworth, Hertfordshire, Gervi Chain manufactures leaf chain, anchor bolts, pins and pulleys for the materials handling industry, often according to clients’ individual requirements. Gervi Chain is well-known for providing exceptional quality and service and aims to work closely with clients’ design, engineering, procurement and scheduling departments to provide solutions for all their leaf chain needs. Gervi Chain also frequently supplies entire package solutions for OEM build programmes.

As the only leaf chain manufacturer represented by the BITA (British Industrial Truck Association) and the FLTA (Forklift Truck Association), Gervi Chain is also a key source of technical information and application assistance for both equipment manufacturers and operators. Gervi Chain representatives are regularly in attendance at the esteemed BSI Technical Policy Committee meetings and ensure that the company is always at the forefront of the latest chain manufacturing standards, improving the quality and safety of products and procedures for all. Gervi Chain holds ISO 9001:2000 for the manufacture of chain and associated machined products.

As each Gervi subsidiary focuses on a particular niche product, the group as a whole is able to offer customers highly specialised chain and associated parts for a wide range of different industries and applications. Customers are able to order their required chain (including leaf chain, conveyor chain, roller chain, sawmill or sharp top chain) from their local Gervi branch which will then be shipped from the factory where it is produced.

Roller chain (ISO & ANSI) is known for its high strength and persistent fatigue durability. The sizes fully compliy with ANSI standard. It can be assembled into single-row, double and many rows applying to the transmission power and different configuration space.

According to different working environments, there are different chains with galvanization, nickel plating, chromium plating and Dacroment treatment for you to choose. All surface treatment modes do not contain hexavalent chromium.

Based on the transmission roller chains, various attachments like types A, SA, K, SK, and D can be installed according to different functions, forming the most widely used chain products in the field of materials transportation which are appropriate for diversified demands of different industries.

The experimental data show that abrasion of chains is related to the selected lubricating oil. Hengjiu can provide oil film for surface rust protection when the roller chain leaves factory, which can lubricate and reduce friction for a long time; meanwhile, its quality meets EU REACH specification and is more environment friendly.

Sewage treatment transmission chain for work plants Drive Bush Bar Screen chains

AOZHOU is one of the professional heat treatment 45mn 316ss sewage treatment transmission chain for work plants drive bush bar screen chains manufacturers and suppliers. Located in Hangzhou, China, we enjoy convenient transportation. Welcome to buy the high quality products of Gervi made in China from our factory.